We are the only manufacturer in China which can produce carbide blank and finished cutters. We have automatic CNC cutter grinding technology and inspection.

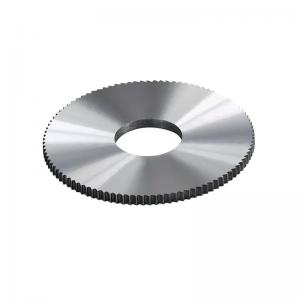

Circumferential tooth profile of milling cutter and the axis of the inner hole which is paralleled called flat tooth milling cutter , the others unparalleled called moulding tooth milling cutter, which has single angle, asymmetrical double angle, symmetrical double angle, convex and concave arc milling cutter, milling cutter for key slot and the other special tooth milling cutter. The most commonly used, of course , is the flat tooth saw blade milling cutter. The whole one made by cemented carbide materials is called integral solid carbide milling cutter (flat tooth series) and integral forming tooth milling cutter. If there is no special requirements, the integral carbide milling cutter can be produced which noted below six main factor: the outer diameter×thickness×inner diameter×teeth number ×with(without) boss diameter--material to be cut according to the international practice

1. Features

Produced according to the international standard ISO2296 and GB/T14301-93. Mainly used for milling slot and milling off process of ordinary steel , iron, copper, aluminum,especially stainless steel, hardened steel, titanium alloy, printed circuit board and other unmanageable material. Compared with HSS ( white steel), carbide milling cutter’s lifetime is much higher, more accurately, better finish, higher cost performance and efficiency, it’s the advanced replacement of the imported cutting tools.

2. Parameters of Material

The material grade is the international standard grade K10~K30, or other carbide with ultra-fine particle structure. Density: 14.6~14.8g/cm³; hardness HRA” 90~92.5, bending strength≥3500MPA, imported cemented carbide material can be used if there is any special requirements

3. Features of the Structure

The national standard of the integral carbide milling cutter stipulate that the outer diameter D≤63mm, the surface is generally without any boss, boss can be produced on the surface3 of the outer diameter >63mm. D≤63mm, thickness≤5mm, inner hole can be without any key way, when the D≥70mm, thickness >5mm, the key way should be made out of the inner hole. The sharp corner of the key way should be connected smoothly with small circular arcs to avoid the sharp corner’s cracking which caused by stress concentration.

4. USAGE: Cemented carbide round milling cutter mainly used in processing alloy steel, stainless steel, high strength steel, titanium alloy, nonferrous metal and nonmetallic material. They are also suitable for cutting wall and floor tiles, paper, adhesive paper, rubber, leather, et. Its lifetime is longer than high speed steel . the cutter is flat , good finished, wear resistant, high efficiency.

5. The milling cutter can regrinding after use, Its life time is the same with the new cutter.

Cutter specification

Out Dia | Thickness | Inner Dia | teeth | Out Dia | Thickness | Inner Dia | teeth |

10 | 0.15~4.0 | 4/ 5 | 6-24 | 75 | 0.5~8.0 | 16/ 22/ 25.4 | 30-120 |

12 | 0.15~4.0 | 4/5/6 | 6-30 | 80 | 0.5~8.0 | 22/ 25.4 | 30-128 |

16 | 0.15~4.0 | 5/6/8 | 6-40 | 85 | 0.5~8.0 | 22/ 25.4 | 30-128 |

20 | 0.15~4.0 | 5/6/8 | 6-45 | 90 | 0.5~8.0 | 22/ 25.4 | 30-160 |

22 | 0.2~5.0 | 5/6/8 | 8-50 | 95 | 0.5~8.0 | 22 /25.4 | 30-160 |

25 | 0.2~5.0 | 6/8/10 | 10-56 | 100 | 0.5~8.0 | 22/25.4/27 | 30-160 |

30 | 0.2~5.0 | 6/8/10 | 10-60 | 105 | 0.8~8.0 | 22/25.4/27 | 30-160 |

32 | 0.2~6.0 | 6/8/10/12.7 | 10-60 | 110 | 0.8~8.0 | 22/25.4/27/32 | 30-180 |

35 | 0.2~6.0 | 8/10/12.7 | 10-60 | 115 | 0.8~8.0 | 22/25.4/27/32 | 30-180 |

40 | 0.2~6.0 | 8/10/12.7 | 10-80 | 120 | 1.0~10.0 | 22/25.4/27/32 | 30-240 |

45 | 0.2~8.0 | 10/12.7/16 | 10-80 | 125 | 1.0~10.0 | 22/25.4/27 | 30-240 |

50 | 0.2~8.0 | 10/12.7/16 | 10-100 | 130 | 1.0~10.0 | 22/25.4/27/32 | 32-240 |

55 | 0.2~8.0 | 12.7/16 | 24-120 | 150 | 1.0~10.0 | 22/25.4/27/32 | 40-240 |

60 | 0.2~8.0 | 12.7/13/16 | 24-120 | 160 | 1.0~10.0 | 22/25.4/27/32 | 40-280 |

63 | 0.2~8.0 | 12.7/13/16 | 24-120 | 180 | 1.5~12.0 | 25.4/27/32/40 | 60-280 |

70 | 0.2~8.0 | 16/22/25.4 | 28-120 | 200 | 1.5~12.0 | 25.4/27/32/40 | 60-280 |

Why Choose Us:

1. You can get the good quality material according to your requirement at the competitive price.

2. We also offer EXW, FOB, CFR, CIF prices. We suggest you to do deal for shipping which will be quite economical.

3. The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

4. We guarantee to give a response within 24hours.(Usually in the same hour)

5. You can get stock alternatives, mill deliveries with minimizing manufacturing time.

6. We are fully dedicated to our customers. If it is impossible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

Factories & Exhibitions

CONTACT US

Phone&Wechat&WhatsApp: +8615116099618

Inquiry:info@dongyatool.com